An Introduction to Oil Pump Jacks: An Industry Icon

.2506241600550.jpg)

Whether on a TV screen or outside the car window, we see this symbol of oil production everywhere: the oil pump jack. It became a key feature of land-based oil production in the 19th century, and it is still heavily relied on to this day around the world. Oil pump jacks extract crude oil when there isn’t enough natural pressure for oil to gush out unaided, or, in other words, when artificial lift is needed.

While these pump jacks play an essential role in making our oil-dependent world go 'round, their ubiquity and usefulness also come with occupational, environmental, and toxic exposure risks. For instance, the counterweight on a pump jack can weigh up to 20,000 pounds, meaning they can easily crush a person without slowing down at all. Every year, one American oilfield worker will be killed and dozens more workers worldwide will die while performing pump jack work-over operations.

If you live near oil pump jacks, if one is on your property, or if you know someone who works in the industry, you may wonder if these or other safety risks can affect you or the people you care about. If you’ve driven past oil pump jacks for years and wondered how they work, if the one you’re seeing is active, or if you can own one yourself, this article series is for you. First, we’ll familiarize ourselves with what oil pump jacks are and how they operate before discussing some of the safety risks.

The Origins of the Oil Pump Jack

The technical origin of the oil pump jack can be traced as far back as 2,250 years ago to wells and irrigation systems in ancient China. During this time, water-well drilling and water piping relied on similar mechanics that the first oil well in the U.S. would one day use. Around the year 347, China began using this technology to drill the world’s first oil wells, affixing bits to bamboo poles to drill as much as 790 feet into the earth to bring up oil. This oil was used in salt production and, according to most historians, it was likely used for lighting and heating as well.

It wasn’t until 1859 that technology like this would be used in America. A passing academic, George Bissel, saw people in Titusville, Pennsylvania, skimming oil off the water of a creek. After taking a sample and confirming in a lab that it could be used as fuel, he financed the invention of a hand pump that could extract oil from the ground, similar to how people were already pumping water out of the ground.

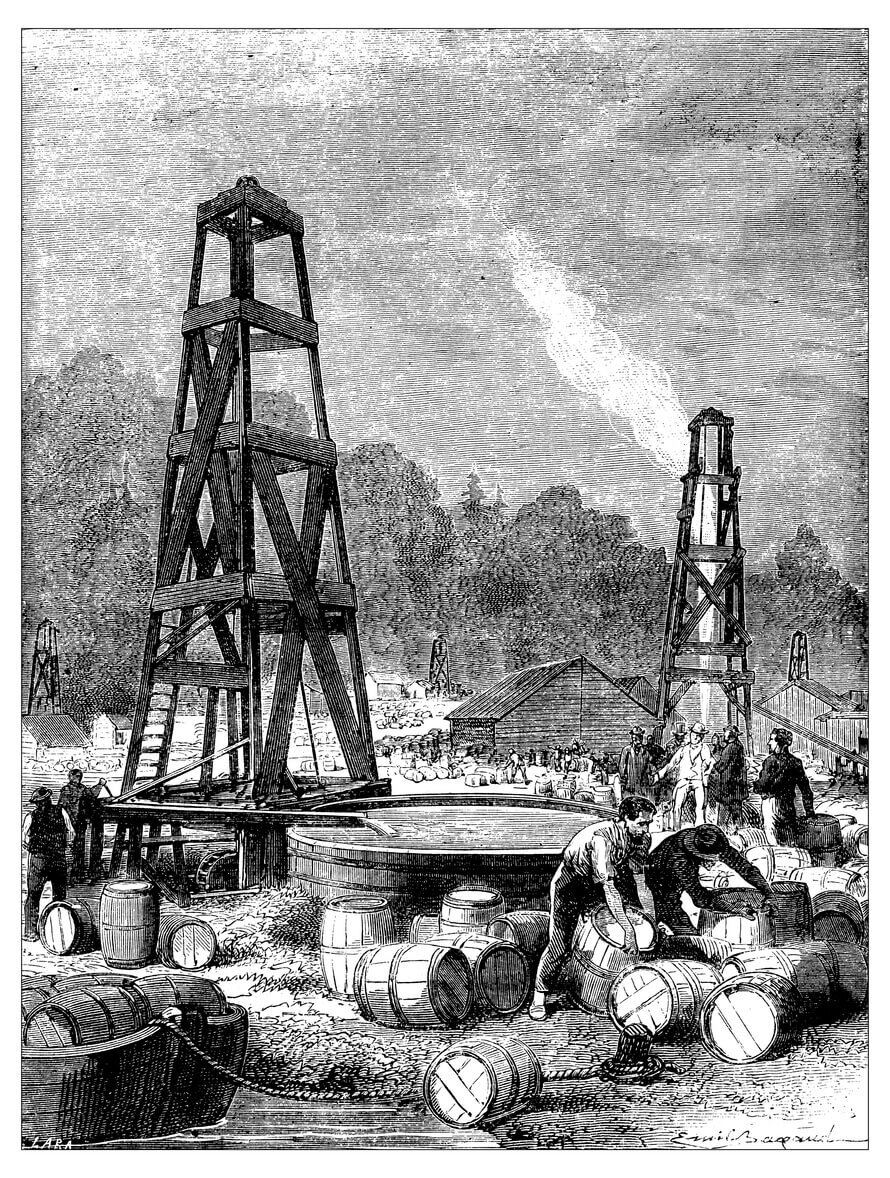

While Bissel initially funded this oil pump venture, he gave up after early iterations failed. A man he had hired, Edwin Drake, continued searching for a way to make the system profitable. His drill finally struck oil on August 28, 1859, reaching nearly 70 feet below ground. The next day, Drake’s drilling team was able to show off tubs, barrels, and washbasins that were filled to the brim with oil. This first successful American oil well used salt-well drilling methods to bore underground, a precursor of the future oil pump jack. While Drake unfortunately didn’t patent his invention and, thus, didn’t ultimately profit from his breakthrough, many others did.

![]()

This type of oil pump required a great deal of manual labor and horsepower to operate.

How We Got to the Modern Oil Pump Jack

The true inventor of our oil pump jack was a sawmill machinery salesman, Walter C. Trout. He held many sawmill-related patents and worked for Lufkin Foundry & Machine Co. (now just Lufkin Industries). When deforestation essentially meant the end of sawmill manufacture and sales around 1920, Lufkin went into oil drilling and refining machines, but still used oil pumps like the labor-intensive ones that Edwin Drake had invented. In 1925, Trout came up with the modern design of the oil pump jack, one that had a counterbalance and could continuously and automatically pump.

This oil pump jack took at least a year before it started to catch on, mainly due to its now iconic appearance—it was initially scorned as ridiculous-looking. Now the oil pump jack is relied on the world over and sold in ever-increasing amounts throughout North America.

Due to its appearance, the oil pump jack has earned many nicknames, including but not limited to:

- Thirsty birds

- Donkey pumper/nodding donkey

- Oil horse

- Rocking horse

- Grasshopper pump

- Horsehead pumps

- Big Texan

- Dinosaur

- Oil bird

- Sucker rod pump

One thing that these oil pump jacks cannot be called is an oil derrick. While these names might be used interchangeably in informal settings, they are mechanically much different. Oil derricks have different valves and motions, as well as slower extraction rates than oil pump jacks, and they mainly refer to hoisting structures. Edwin Drake’s original oil pump was shaped rather like a derrick, while the modern oil pump with its seesaw pumping motion is an oil pump jack.

How Oil Pump Jacks Work

Oil pump jacks use a reciprocating system to lift oil to the surface, reaching down the well to pressurize the area and force oil up to the surface through tubing. This tubing feeds the mixtures of oil and water, gas, and other chemicals to the equipment that will separate those resources.

To break down the process further, we’ll first need to describe some of the different parts that apply to most oil pump jacks:

- Horsehead: The curved metal piece that bobs up and down, at the front of the walking beam.

- Walking beam: The horizontal beam that seesaws, connected to the horsehead.

- Sampson Post: The Sampson Post is the upright A-frame that supports the walking beam.

- Pitman arm and counterweight: The pitman arm connects the walking beam to the counterweight, and both the pitman arm and counterweight provide balance.

- Crank or crankshaft: The crank is the smaller arm attached to the counterweight. Powered by the motor or engine behind it, the crank rotates, moving the counterweight and pulling on the pitman arm so it can move the walking beam.

- Polished rod and sucker rods: This series of rods is connected to the horsehead at one end and the downhole pumping unit on the other.

- Tubing and casing: Protects the downhole pumping unit and lets oil flow up without leaking.

The electric or gas motor is officially known as the “prime mover.” As it powers the crankshaft’s rotation, the walking beam begins to move in a seesaw motion. As the walking beam moves, the horsehead pulls up the polished rod and the attached sucker rods, then sends the rods back down. This causes a plunger pump to draw oil into the tubing through one-way valves.

In general, how this reciprocating plunger pump works is with a riding or traveling valve at the bottom end of the sucker rods, while a standing valve sits at the bottom of the well. When the sucker rods are pulled up, its riding valve closes, and the standing valve opens at the bottom of the well, drawing oil up into the well. On the downstroke, the sucker rod’s riding valve opens, and the well’s standing valve closes, sending the oil through the other side of the riding valve. The standing valve is a check valve that keeps the oil flowing in just one direction: up. This eventually brings oil up to the surface, where it can be collected, then transported.

On average, a pump jack will complete an upstroke and downstroke pump 20 times in a minute, often moving 1 to 10 gallons of crude oil at every stroke. Over the course of a day, an oil pump jack might yield 5 to 40 barrels of crude oil, which is significant only because these pump jacks tend to be used for stripper wells, sites where oil reservoirs are running low.

Oil Extraction Around the Clock

Oil pump jacks can pump 24/7 in on-off cycles. These cycles determined based on calculations on what would be most cost-efficient, whether that’s 15 minutes pumping then 15 minutes off throughout the day, or even 12 hours on then 12 hours off.

The range of possible operating schedules depends in part on the fluids involved, whether it’s a well that has both crude oil and water, or if natural gas and other chemicals are also heavily involved. A company must determine how long to let fluid collect, and when any additional pumping would simply be wasted effort that doesn’t draw out any more fluid. Each well needs different amounts of pressure to maximize oil extraction.

Why Oil Pump Jacks Are So Common

Older versions of oil extraction could draw out only 25-50% of a well’s oil, while the pump jack can now ensure that just about an entire well’s worth of reserves can be extracted. When it comes to stripper wells, or oil wells where most of the oil has been extracted already, oil pump jacks can be used to steadily keep up oil production, albeit at a rate of usually no more than 10 barrels of oil per day. This means that low-reservoir wells can keep producing long after natural pressure has been lost or nearly lost.

It is possible to use pump jacks in the initial stages of oil drilling, but higher volume oil wells are not a good fit for oil pump jacks. Typically, the first month or four after drilling and fracking, artificial lift isn’t needed. It’s not until natural pressure is drastically reduced that some sort of rod lift system would be used.

Most modern oil pump jacks can drill between 600 to 7,000 feet, though there are pump jacks that can drill up to 10,000 feet underground. The deeper the oil reserve, the bigger the oil pump jack needed.

Oil Pump Jack Maintenance

While oil pump jacks are capable of running reliably around the clock and lasting for decades, it takes careful maintenance to ensure that they operate smoothly and safely. As with any equipment, regular inspections are key.

Some key examples of oil pump jack maintenance include:

- Every day, one needs to check for any leaks, loose nuts and bolts, etc. The right lubricants in the right amounts must also be applied regularly to keep things running smoothly.

- Every week, it’s necessary to walk around the entire pump and watch each component for a full rotation to check for any off-kilter movements, strange sounds, or vibrations.

- Every month, the gearbox, which connects with the prime mover and the crankshaft, needs to have its fluid levels checked and be inspected for leaks. Worn-down equipment, such as various bearings and bolts, will likely need to be lubricated, and one must also check the alignment of pitman arm safety pins.

This maintenance should only ever be done by prepared professionals. Even these routine steps come with serious hazards. In fact, oil pump jacks shouldn’t be approached at all unless you are a fully trained and properly equipped professional.

The Risks of Oil Pump Jacks: An Introduction

While oil pump jacks are commonplace, their presence still brings uncommon safety risks.

These risks include but certainly aren’t limited to:

- The counterweights weigh up to 20 tons and are able to strike and even crush a person without ever slowing their movement or momentum.

- Cables that run along the machine can slice your hand off if you try to grab them.

- The electricity that powers oil pump jacks is high voltage, so electrical boxes, wires, and other equipment can present electric shock and fire risks.

Oil pump jacks don’t need personnel to constantly monitor their motion, and the start of a new work cycle is often automated. This means there is often no warning as to when an oil pump jack will go from stationary to moving.

That means it is not safe to approach an oil pump jack—even if it’s not moving.

There are far too many instances of idle pump jacks attracting teenagers as an oddity or even a playground of sorts to investigate and clamber onto. Kids have tried to ride the pump jacks or play around them and have been seriously injured by the machinery, especially when it springs into motion unexpectedly because of automated settings—and because the site lacked necessary warning signs.

Even if you never approach an oil pump jack, the power lines that run along a property can spark fires, and the oil and gases it produces can create community-wide health risks. As an experienced oilfield worker, you could face preventable jobsite hazards because of negligent management and faulty corporate decisions.

What to Do About Oil Pump Jacks Close to or on Your Property

If there is an oil pump jack sitting on your property, or if you live within a mile of one, you could have legal recourse to demand safer drilling operations and a safer environment. If you or someone you know works at an oilfield or with oil pump jacks, it’s also important to know what your rights are at a worksite and after any workplace accident. You can take advantage of resources that inform you of your legal rights and options, and you can speak to an attorney to get detailed answers to more specific questions, especially if you are already facing an injury or wrongful death claim.

While oil drilling operations and, thus, oil pump jacks are a necessary part of our economy and transportation, this unfortunately does not mean that the corporations using these vital machines are doing so responsibly, safely, or even legally. Whatever your proximity to oil pump jacks, you deserve to know what your legal rights are and how to stand up for them.

For Further Reading on Oil Pump Jacks:

- Categories