When Forklifts Kill: Understanding Strikes, Tip-Overs & Other Preventable Workplace Deaths

In Louisiana, a 21-year-old driller was removing a blowout preventer from a wellhead, the blowout preventer being hoisted up by a chain placed on the forks of a forklift. The chain slipped off, and the blowout preventer fell on the young driller, killing him. That same month, an employee in Georgia was performing maintenance on a forklift, which had been set up on some blocks. The forklift rolled off the blocks and fatally struck the employee. Shortly thereafter, an employee in Texas got out of a forklift, which rolled and then pinned down his foot between the forklift and a container. The worker fell back, was knocked unconscious by the blunt force trauma, and later died from the injury.

While these tragedies all had different causes, every one of them could have been prevented by the employers involved. In each case, and so many others like these, the Occupational Safety and Health Administration (OSHA) cited and fined the employer for numerous safety violations. Yet those citations and fines came too late to help the employees who truly paid the price for their employers’ negligence.

These weren’t accidents and violations that happened decades ago either. Each of these tragedies occurred in the same month, in February of 2025, even though employers have known for decades the simple steps it takes to prevent such deadly forklift accidents.

Forklifts are one of the most common and useful pieces of industrial equipment, but every year, forklifts still kill dozens of workers and injure tens of thousands more across the United States. According to the National Safety Council, forklifts caused 15,480 nonfatal on-the-job injuries from 2021 to 2022 and 67 deaths in the workplace in 2023. Despite numbers like these each year, and forklifts being found everywhere around warehouses, construction sites, and manufacturing facilities, forklifts remain one of the most underestimated industrial dangers.

Why Forklift Overturns Are Deadly

While they may not look it, forklifts can often weigh 7,000 to 9,000 pounds. That means a forklift can weigh a ton or two more than the average pickup truck. When a forklift falls onto someone, the forces involved are crushing and often fatal. When a worker is pinned down by a forklift, they won’t be able to escape on their own.

Most Common Types of Forklift Accidents

Often referred to as “powered industrial trucks” or “PITs”, forklifts have been a known hazard in various industries for decades.

Some of the most common types of forklift accidents include:

- Struck-by hazards: This is when a moving forklift hits another worker, most often while the forklift is reversing or turning corners.

- Pinning or crushing injuries: This is when a worker is trapped by the forklift against a wall, rack, or another piece of equipment, often while the forklift is reversing.

- Tip-over accidents: When a forklift overturns, it can trap operators or crush them beneath thousands of pounds of metal.

- Falls from forklifts: Forklift passengers can fall to their deaths, either from the fall itself or then being run over, especially if they’re being raised on a platform or on the forks.

- Falling loads: If not properly secured on the forklift, all manner of tools and items can cause injuries or death if they fall on workers.

The Dangers of Forklift Tip-Overs & How to Prevent Them

According to the National Institute for Occupational Safety and Health (NIOSH), roughly 25% of deaths caused by forklifts are caused by overturns. And deaths by forklift tip-overs or overturns are highly preventable. An overloaded forklift or improperly balanced loads can shift the center of gravity, destabilizing the forklift. Forklift tip-overs can also happen when surfaces are uneven, such as at outdoor construction sites, aging facilities with cracked concrete, and so forth.

Who is at fault for forklift tip-overs? Typically, an employer, often for inadequate floor maintenance and/or inadequate training for forklift operators.

With inadequate floor maintenance, workers have to navigate forklifts on:

- Oil spills

- Water-slicked paths

- Ice

- Debris

- Dock plates that aren’t secured

- Other hazards that cause a forklift to lose traction or lurch

When an employer fails to train forklift operators properly, operators might:

- Make sharp turns

- Travel with elevated forks

- Travel with improperly loaded cargo

- Brake suddenly on inclines

- Try to jump clear of a forklift during a tip-over

These and other mistakes can quickly trigger a tip-over or put another worker directly in the path of unstable heavy equipment.

For instance, if not trained properly, a forklift operator may not know that the safest thing to do in the event of a tip-over is to stay in one’s seat, seatbelt fastened, bracing against the steering wheel as you lean the opposite direction of the fall. In stand-up forklifts, the safest thing to do is step back during a lateral tip-over. These can be counterintuitive ways to avoid being crushed by the forklift. If an operator reacts naturally by trying to leap out the side of an overturning forklift, this can put them at higher risk of being trapped and crushed by the forklift.

These types of potentially fatal errors are not the result of simple carelessness. They are natural responses that require intensive training to counteract. It is the responsibility of employers to ensure that forklift operators are well trained and vetted, and supervisors need to maintain a culture of not cutting corners for the sake of production schedules. It is up to employers to make sure that forklift operators know how to keep themselves and others safe around such heavy equipment.

The Danger of Forklift Underride Accidents

Operators of a stand-up forklift face a particularly insidious hazard: underride accidents. This is when the forklift backs up and pins the operator against a fixed obstacle, such as horizontal rack beams or shelving, and the forklift keeps backing up and slips under the shelving while the operator is trapped, crushing and/or asphyxiating the operator between the beam and the front of the operator compartment.

Whether at a warehouse, distribution center, or another site with potential underride hazards, supervisors should know about these risks factors and provide training to operators accordingly. This would mean exhorting operators to keep their eyes looking back whenever they’re reversing a forklift, or to use a spotter, someone who watches as the operator reverses.

More simply, adding a rear guard and corner posts to these stand-up forklifts can save life and limb. These physical components of a forklift can prevent forklifts from moving underneath a shelf area and keep the operator from being pinned against anything. Of the nine deaths and three severe crushing injuries reported to OSHA in underride accidents (from 1993 to 2008), none of the forklifts had corner posts or protective rear guards.

The Dangers of Forklifts to Pedestrians

One of the realities of forklift deaths is that many victims are not the ones operating the forklift. Whether it’s a coworker walking nearby, workers guiding loads, or spotters positioned too close, many workers trust that forklift operators can see them and that safety protocols are being followed. However, if something goes wrong, workers on foot have no time to react. Forklift operators have blind spots, and any elevated loads mean that an operator cannot see people who are directly in front of or behind them. If an aisle is narrow or turns are tight, pedestrians can quickly be in the path of a forklift with no escape route to take.

In March of 2025, a 45-year-old man was run over and killed by a forklift after crossing a road at a Georgia facility. The forklift operator—who worked for a different company—was on the phone at the time of the collision. This distracted operator ran over the man, and then instead of rendering aid to the bleeding man, the forklift operator fled the scene. While OSHA cited one company for the 45-year-old not wearing a high-visibility green vest, the forklift operator’s employer was fined for several serious safety violations. This tragic accident occurred at a worksite that had fielded 53 calls for emergency services in the 16 months prior, more than 12 of which were for traumatic injuries.

According to OSHA, if a forklift operator can’t see in the direction they’re moving, they must have a spotter. When they are crossing paths or going around corners they can’t see, a forklift operator must slow their speed and sound the horn. These and other basic, common-sense protocols are routinely ignored in some workplaces, and whenever that’s the case, it is a sign of employers who have failed to uphold their responsibilities. This includes the responsibility to make sure that workers understand safety protocols and abide by them, especially when it comes to dangerous machinery such as forklifts.

Even when pedestrians aren’t killed in forklift accidents, the results can still be severe. According to the Bureau of Labor Statistics (BLS), pedestrians injured by forklifts accounted for the highest median days away from work compared to other nonfatal injuries from a forklift.

The Solutions for Forklift Safety Are Proven & Simple

When OSHA has investigated injuries and deaths from forklift accidents, certain patterns have reliably emerged. Time and again, employers were found to have failed their workers, committing a wide range of safety violations.

These consistent failures by employers include and aren’t limited to:

- Failing to equip forklifts with seatbelts or to ensure that operators are wearing them

- Not properly training, evaluating, and supervising forklift operators

- Not providing safety signage

- Neglecting to repair and maintain forklifts in good, safe condition

- Not ensuring that loads were stable, balanced, safe, and not exceeding the forklift’s weight capacity

- Not creating enough clearance in aisles, loading docks, doorways, or other passages and turns for forklifts to safely operate without obstructions

Whether it was for poor lighting, inadequate barriers, inadequate traffic controls, or other failures, employers were consistently cited for failing to prevent struck-by and crushing hazards from forklifts at their worksites. These are all common-sense policies that have been in place for decades; employers are not being called out on niche or obscure guidelines.

OSHA has established clear standards for powered industrial trucks that apply across industries, such as:

- Adequate space in aisles, loading docks, and doorways to prevent clearance or obstruction hazards

- Cleared, sturdy surfaces to navigate that are free of clutter, debris, or overgrown vegetation

- Secure storage that prevents sliding or falling materials

- Warning signs for clearance limits

- Covers and guardrails that protect workers from open vats, ditches, and drop-offs

These and other safety protocols fall under the duties of an employer. Straightforward policies like worker training, well-designed job sites, and properly equipped forklifts shouldn’t have to be spelled out in order for companies to follow them. They are easily achievable safety standards that can eliminate hazards that forklift operators and pedestrians face. Yet forklift accidents keep happening across many different industries.

Why Forklift Injuries & Deaths Continue Despite Known Risks & Prevention Methods

The Material Handling Equipment Distributors Association looked at data from the National Safety Council and Bureau of Labor Statistics.

They found that that in 2021-2022:

- Trade, transportation, and utilities had the highest rate of forklift deaths (50.7% of deadly accidents)

- Manufacturing facilities (25.4% of deadly forklift incidents)

- Construction (accounted for 18.3% of forklift deaths)

In these industries in particular, danger can often be normalized by companies. Abiding by safety standards to the letter can be perceived as red tape that gets in the way of real work, or at least as a hindrance to meeting all-important quotas and deadlines.

The thing is, safety guidelines haven’t changed much since NIOSH issued its original comprehensive alert in 2001, based on data from the 1980s and 1990s. Yet forklift deaths haven’t been prevented like they should.

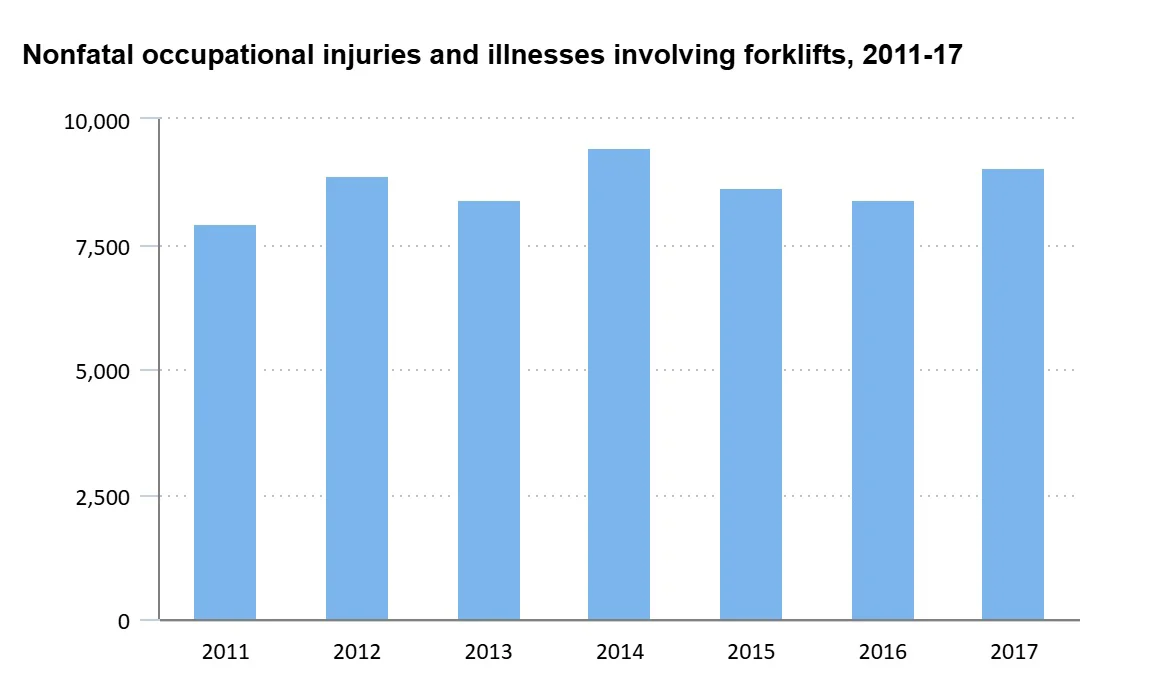

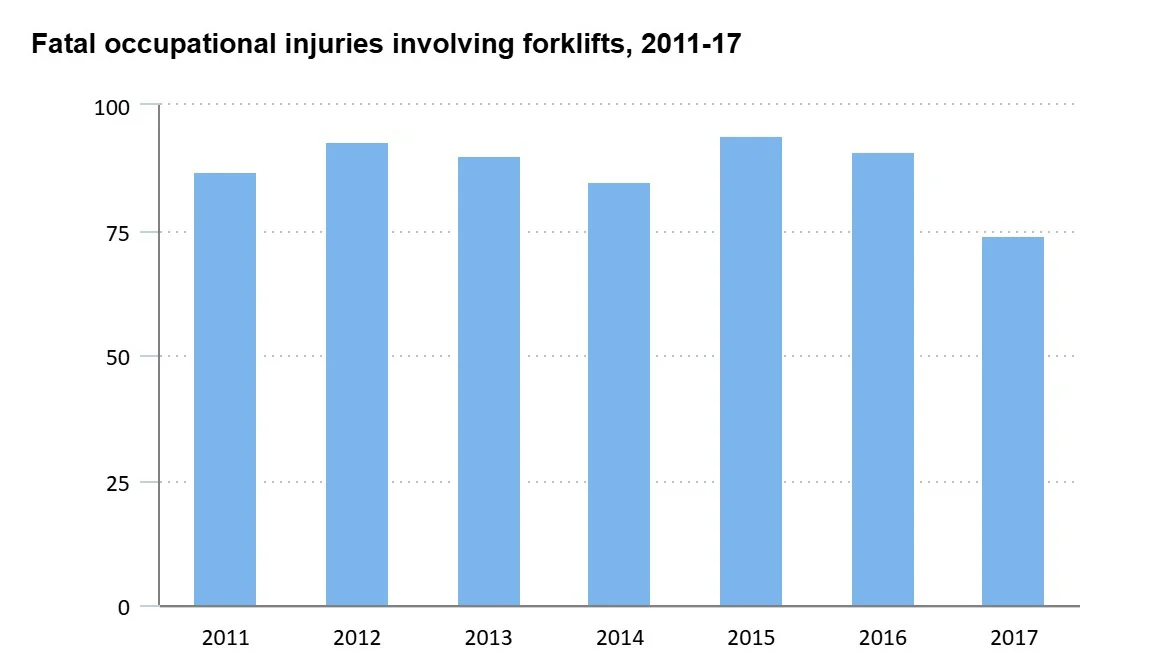

According to BLS data, there were 87 fatal injuries from forklift accidents in 2011, and 74 such deaths in 2017. Nonfatal injuries actually increased from 7,920 in 2011 to 9,050 in 2017.

Every year from 2011 to 2017, reports of forklift injuries reached more than 7,500.

Data from the BLS shows a steady or sometimes increasing rate of deaths from forklift accidents from 2011 to 2017. There were 90 or more forklift fatalities in 2012, 2013, 2015, and 2016.

These accidents keep happening, but basic safety rules still aren’t being followed to prevent such accidents from happening again. When companies are investigated and cited for fatal forklift accidents, the fines are often shockingly low. In the gruesome hit and run of a 45-year-old in March of 2025, two companies were fined a total of about $10,000.

In the February 2025 accidents reported at the beginning of this article:

- The company where the maintenance worker was killed by a forklift was initially fined $30,452, which was brought down to $16,550.

- The employer of the worker who was knocked unconscious and later died was fined just $29,792 at the outset, and even this was brought down to $17,213.

- The company where a young man was killed by a blowout preventer slipping off of a forklift was only fined $14,895.

This sends a clear message that worker safety takes a back seat to profits.

What Workers & Families Should Know About Forklift Accidents

Responsibility for a forklift accident often extends beyond the individual operator, as the fault lies with the employers who failed to train and supervise operators sufficiently, failed to maintain the forklift, designed dangerous facility layouts, enforced unrealistic production quotas that encouraged dangerous speeds, or ignored other known hazards.

Workers and families have the legal right to hold negligent employers accountable, not just for their immediate losses but also for the pattern of decisions that made the forklift accident inevitable.

These cases involve more than operator error. They involve employers who valued productivity over human life, who ignored safety standards that have existed for decades, and who have treated worker deaths as acceptable costs of doing business. If someone you love was killed or seriously injured in a forklift accident, you deserve answers, accountability, and justice.

- Categories