Understanding Safety Regulations for Chemical Plants

Per the U.S. Occupational Health and Safety Administration (OSHA), toxic, reactive, and flammable substances may result in catastrophic injuries and accidents. It doesn't matter what type of industry is using the chemicals—they still pose a threat to worker safety and well-being. Generally speaking, these substances become dangerous when they are released. When a substance is released, it may cause an explosion. Because of this danger, OSHA has created specific safety guidelines that must be followed by chemical plant employers and employees.

Although safety regulations are used primarily to keep employees from suffering serious injuries, they serve other purposes, too. For example, employees will feel valued by their employers when they know that their safety is important. Additionally, safety procedures make sure that chemical plant workers are able to return to work the next day. Without a chemical plant, workers would not be able to collect paychecks or continue work. Safety procedures help companies stay productive by avoiding accident-related shutdowns and other unnecessary interruptions.

According to OSHA, proper training is the most effective way to keep employees safe.

The Most Important Safety Guideline: Training

Ignorance can easily lead to a deadly chemical plant accident. Because of this, employers are responsible to provide initial training for new employees. If an employer fails to properly train new workers, he/she may be held liable for any accidents and injuries caused by the new employees. Employees should have a clear understanding of the operating procedures of the plant. Additionally, the training must emphasize chemical plant employee safety and safety operating procedures. Per OSHA, all training must include information regarding emergency procedures and health hazards related to the work.

After the employer has provided initial training, refresher training must be offered every three years. If the employer believes that refresher training is necessary before the three years are up, they may require employees to participate sooner. Refresher training is designed to help employees remember, understand, and are practicing all of the proper safety procedures related to their jobs. Your employer is responsible to make sure that refresher training is given. During training, your employer should keep a written record indicating the date of the training, that you participated, and that you understood the training.

Avoiding Chemical Plant Accidents

Enacting and enforcing safety precautions is imperative in minimizing potential catastrophes.

There are dozens of procedures and a host of equipment to protect chemical plant workers:

- Carbon monoxide and other gas detectors

- Earplugs

- Fire extinguishers

- Flammable safety cabinets

- Frequent training on safety procedures

- Hydrostatic tests to check pressure

- Protective eyewear

- Eye-washing equipment for splashes

- Protective clothing

- Protective gloves

- Safety valves to regulate the pressure

- Ventilation and respiration for fumes

Investigating Incidents

Per OSHA, one of the most important parts of safety management is the investigation. When a dangerous incident occurs at a chemical plant, your employer must investigate the specifics of the incident.

- When the incident occurred

- When the investigation began

- Details regarding the incident

- What contributed to the incident

- What should be changed to avoid future problems

Filing a Business Interruption Claim

Generally speaking, a business interruption claim allows an insured business owner to file a claim for income lost because of an accident. For example, if you are forced to cease operation at your plant because of an explosion, you may be able to collect compensation for lost income while the chemical plant is repaired. If your business has suffered damage because of a safety law violation, contact Arnold & Itkin to discuss your options—you may be eligible to file a business interruption insurance claim. Our lawyers are skilled negotiators and can help.

Proper Plant Design Can Prevent Future Accidents

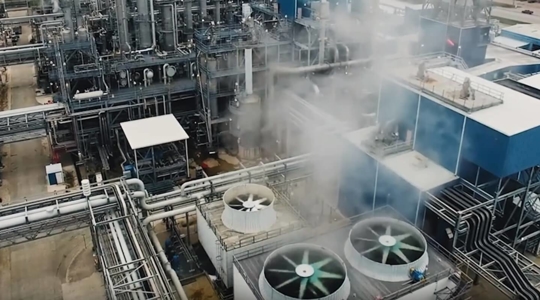

A chemical plant should be designed to decrease hazards and risks, specifically with explosions and overall exposure. Not only that, the design must be done in a way that will also limit the risks for those working at the plant and in the community. What enables the plant locations to be safe and efficient are the necessary routine maintenance checks, as well as frequent employee training. Without these three key factors (design, maintenance, and training) a facility becomes more dangerous and a possible hazard for accidents leading to explosions.

The design of a chemical plant needs to be catered uniquely to the types of materials that will be handled on-site. Taking these points into consideration during the planning stages of the building is absolutely crucial. Why? Because understanding what specific chemicals will be used will determine factors such as the size of the site, different types of operating manuals for facility start-up and shut down, among other details. Before the construction process even begins, plants must consult manufacturers for the equipment they will need (in order to provide adequate spaces for each tool), as well as laboratories for testing. Aspects that need to be taken into consideration when building a plant also include not only the size of the location but the impact on the environment, operational, capital and maintenance costs, etc.

- Rate of flow

- Working pressures

- Water and electricity availability

- Temperatures needed for specific chemicals

Contact Arnold & Itkin Today at (888) 493-1629 for a Free Case Review

If you have been hurt in a chemical plant explosion because your employer failed to follow safety procedures, you may be entitled to compensation. Arnold & Itkin have helped thousands of clients recover the compensation they deserve. We have recovered billions of dollars on behalf of clients, and this equips us to achieve the best possible results for your case. If you or a loved one has been hurt, call our experienced plant and refinery accident lawyers today. When you contact us, we can help you understand your legal circumstances, rights, and options.

Call today and see what a top-rated attorney from Arnold & Itkin can do for you: (888) 493-1629.